With that being said, A 220v welder will usually require a 10-gauge or 8-gauge wire.

60 amp aluminum wire size how to#

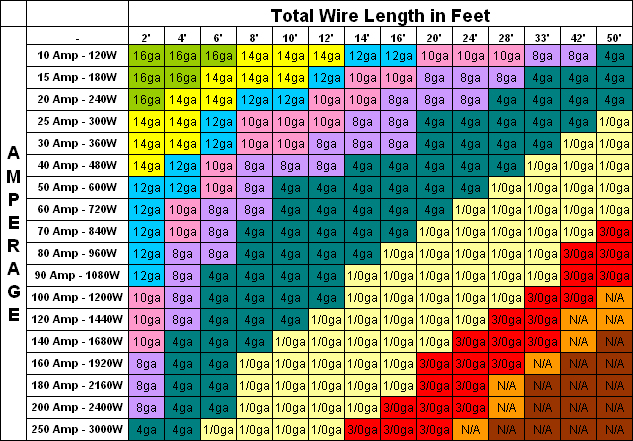

So, without further ado, let’s proceed to the step by step guide on how to hook up a 220 outlet for a welder. A 50-amp circuit breaker and 6-gauge wiring is required for welders with 40 to 50-input Amps. To install the plug, strip about two inches of sheathing from the cord, separate the wires, strip 1/2 inch of insulation from the end of each one and crimp a ring lug onto each wire. 60 electrodes are what I learned on and 6011 is also a good rod. #14 wire = 15 Amp #12 = 20 A #10 = 30 A #8 = 40 A #6 = 50 A #4 = 60 A As for wire size on machine, as long as name plate voltage is supplied to leads of machine/motor, the factory lead can be much smaller than the wire supplying power to the plug or disconnect from the main power supply. Welders need a 40-amp breaker and 8-gauge wire to operate. What kind of wire do I need for a 50 amp welder? It’s always best to size welder circuits and wiring based on the input current requirements of the welder. It is recommended to achieve the full rated output of the welder you would need a 30 amp breaker, 230 volt service with #10 wire. For welders with 40 to 50-input Amps, a 50-amp circuit breaker and 6-gauge wiring is required. It’s worth noting that I calculated this taking 3% voltage drop into account. Wire Connection Type: For Cable OD: Environmental Rating: Specifications Met: Color NEMA 10-50 Male. BTW, I bought a 50' 10ga heavy duty extension cord from Home Depot and replaced the plug and receptacle ends with NEMA 6-50 devices to match up … A bit confused over wiring for the 220 volt plug in. Points to note: The cable to your hot tub will be rated for 50A (not 100A) therefore you must not upgrade the breaker in your main panel to 100A.

0 kommentar(er)

0 kommentar(er)